Exploring the Perks of a Chemical Defoamer in Manufacturing and Manufacturing

The combination of chemical defoamers in production and manufacturing procedures offers a tactical advantage by attending to one of the relentless obstacles in commercial operations: foam control. As manufacturers aim to enhance procedures and improve consumer contentment, the duty of chemical defoamers becomes increasingly important.

Significance of Foam Control

While the existence of foam in producing processes can often appear safe, efficient foam control is vital for maximizing functional performance and item high quality. Foam can disrupt different stages of production, resulting in ineffectiveness that may extend and raise prices handling times. In markets such as food and beverage, pharmaceuticals, and chemicals, uncontrolled foam can obstruct tools, interfere with automated systems, and eventually lead to product disparities.

Applying effective foam control techniques not only improves efficiency yet additionally sustains regulatory compliance in markets where foam can cause ecological problems. By making use of chemical defoamers, manufacturers can reduce these difficulties, making sure smoother procedures and higher-quality final product. Inevitably, focusing on foam control is a crucial aspect of manufacturing that can yield significant benefits in terms of item, security, and effectiveness dependability.

Sorts Of Chemical Defoamers

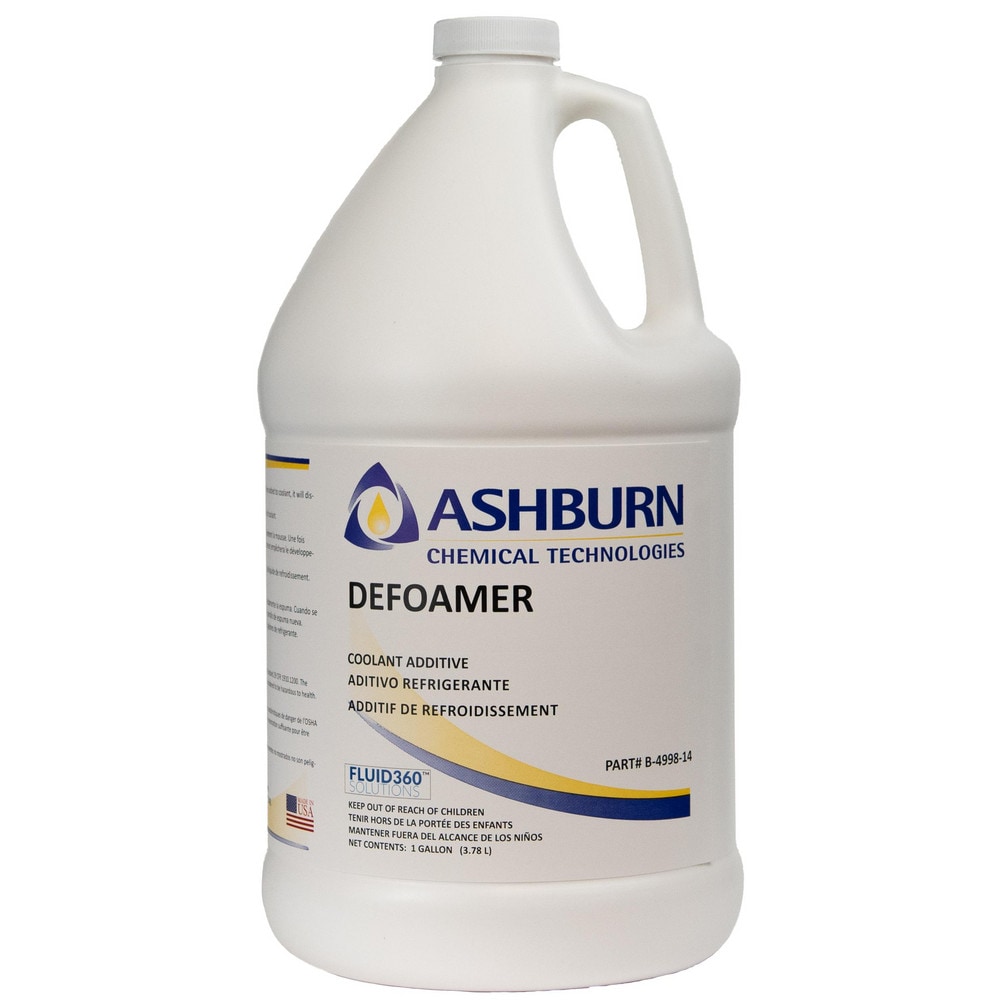

What sorts of chemical defoamers are available for making procedures, and exactly how do they differ in application? Chemical defoamers can be categorized into 3 primary types: silicone-based, organic, and inorganic defoamers. - Chemical Defoamer

Organic defoamers, typically stemmed from fatty acids or natural oils, work in a variety of applications, consisting of food and beverage production. They are commonly favored for their lower poisoning and environmental effect, making certain compliance with industry guidelines.

Each kind of defoamer serves distinctive objectives based on the chemical make-up and the certain requirements of the production process, allowing makers to choose one of the most appropriate option for their specific needs.

Advantages in Manufacturing Performance

Chemical defoamers play an important duty in boosting manufacturing performance by efficiently regulating foam generation during different procedures. Foam can impede manufacturing rates, interrupt tools operation, and cause costly downtime. By integrating chemical defoamers, suppliers can reduce these problems, ensuring smoother workflow and boosted overall productivity.

The usage of chemical defoamers aids optimize the operational efficiency of tools such as activators, mixers, and pumps. With minimized foam, these equipments can operate at their intended capability, lessening the threat of overflow and enabling consistent processing. This leads to far better source utilization and higher throughput.

Additionally, chemical defoamers promote faster handling times by lowering the time required for foam removal. This acceleration can considerably affect right here manufacturing timetables, permitting suppliers to meet customer need extra effectively. Additionally, making use of defoamers adds to reduce energy usage, as machinery operates much more effectively with decreased foam interference.

Effect On Product High Quality

Foam control is not only vital for preserving effectiveness in producing processes but also plays a significant role in ensuring item high quality. Excessive foam can present air right into solutions, bring about incongruities in the last item. This can materialize as problems such as voids, uneven appearances, or poor coatings, which weaken the designated quality and efficiency of the item.

Moreover, foam can hinder the homogeneity of mixtures, causing irregular distribution of active components. In sectors such as finishes, cosmetics, and food production, this can lead to variants in color, preference, and general effectiveness. By utilizing a chemical defoamer, producers can mitigate these threats, making sure that products fulfill rigid quality requirements.

Furthermore, controlling foam can boost the stability of solutions and suspensions, which is crucial for making certain shelf-life and customer contentment. With enhanced item uniformity and decreased problems, manufacturers can accomplish higher requirements of quality control, inevitably resulting in increased customer depend on and brand commitment.

Cost-Effectiveness and ROI

Effective foam control not only boosts product top quality but additionally contributes substantially to the overall cost-effectiveness of producing procedures. Using chemical defoamers decreases foam-related issues, which can or else lead to production hold-ups, tools malfunctions, and my website boosted energy usage. By lowering foam, manufacturers can enhance their procedures, leading to higher throughput and performance.

Investing in chemical defoamers can yield a considerable roi (ROI) The initial expenses linked with these additives are typically countered by the financial savings realized from reduced downtime and enhanced product return. Moreover, improved item top quality can lower waste and rework costs, even more boosting economic efficiency.

Furthermore, effective foam control can result in decreased water and energy usage, contributing to lower operational expenses. This is especially vital in sectors where resource efficiency is critical. By integrating chemical defoamers into their processes, producers can accomplish long-lasting cost savings while maintaining competitive pricing in the marketplace.

Conclusion

In verdict, the combination of chemical defoamers in manufacturing and manufacturing procedures is vital for optimizing functional effectiveness and enhancing item quality. The benefits used by chemical defoamers not only sustain regulative conformity however also supply a competitive side in the manufacturing landscape.

The assimilation of chemical defoamers in production and production procedures offers a critical advantage by resolving one of the persistent obstacles in industrial procedures: foam control.While the presence of foam in making processes can often seem safe, effective foam control is vital for optimizing functional efficiency and product top quality.Chemical defoamers play an important duty in improving making efficiency by successfully controlling foam generation during numerous processes.Additionally, chemical defoamers facilitate faster processing times by lowering the time needed for foam removal. Furthermore, the usage of defoamers contributes to reduce power consumption, look at this now as machinery runs extra efficiently with minimized foam disturbance.